Foam has remained central to architecture, interior design, and comfort products ever since its invention in 1929. Its lightweight physical properties not only make it highly adaptable but also immensely convenient to handle and use in various applications. More importantly, the link between foam, comfort, and aesthetics cannot be understated.

Choosing the right foam supplier, thus, is critical to the success of your business, especially in the realm of interior design, furniture, and home improvement. The confidence of delivering quality to customers in every single product is largely determined by the type of foam used, its durability, and above all, the supplier’s reliability. This article aims to serve as a comprehensive guide on how you can identify and choose the best foam supplier for your business.

Understanding the Basics – The Different Types of Foam

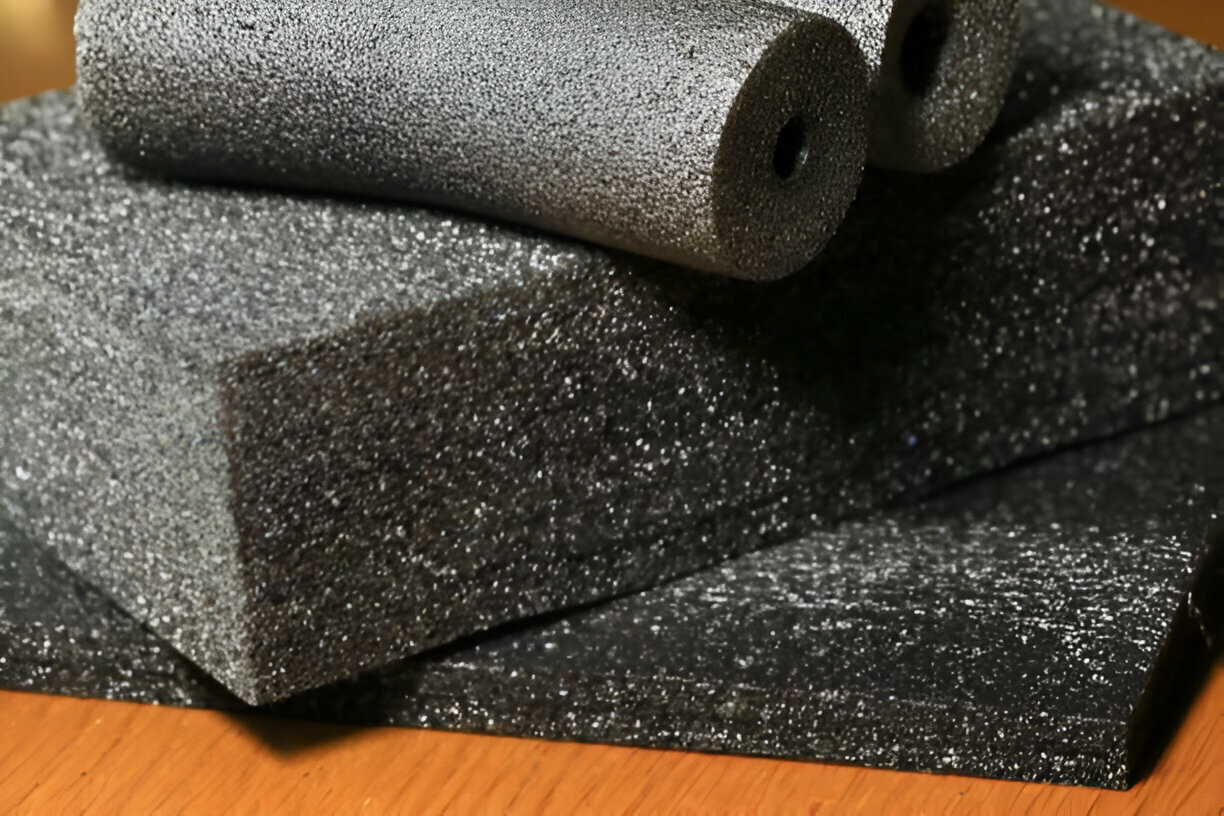

From polyurethane foams, memory foams, and high resilience foams, to more specialised ones like acoustic foam and latex foam, the variety of foam types is astonishingly wide. Polyurethane foam, for instance, is a classic and widely used due to its flexibility and low cost. Meanwhile, memory foam, known for its unique contouring attribute, is favoured for bedding, pillows, couches, and also in medical applications. High resilience foam is predominantly used in high-end furniture due to its excellent comfort lifespan and fast recovery.

Every type of foam finds a unique application in home design and improvement. Understanding these applications is essential when choosing a suitable foam supplier because it directly impacts the potential success of the products you deliver to your customers.

Decoding Quality – What Makes a Good Foam Supplier?

While a deceivingly simple material, the quality of foam can greatly vary depending on several factors such as its density, durability, and firmness. These intrinsic properties have a significant impact on the foam’s performance in different applications and thus, should be carefully analysed while choosing a supplier.

It’s also crucial to check the testing certificates and standards your supplier adheres to, ensuring they meet recognized international or national safety and quality standards. Furthermore, with the increasing importance of sustainability, consider choosing a supplier that follows sustainable practices, uses eco-friendly materials and minimises waste during production.

Questions to Ask Your Potential Foam Supplier

When shopping around for foam suppliers, have a list of essential questions ready. Some questions may revolve around their safety standards, the customisation capabilities they offer, their price points, and whether or not they’ve got a proven history of reliably delivering quality products.

Other practical questions can be about minimum order requirements, delivery timelines and whether they can handle unique, specific requests that could add value to your product line. Doing so will equip you better in your decision-making process while ensuring the supplier fits within your business model.

Key Specialty Foam Suppliers in Australia

In Australia, some reputable suppliers have carved out a niche for themselves in the foam market. Each brings distinct strengths to the table. For instance, EVA Industries and Foamex are known for their wide range of quality foam products. Meanwhile, Foam Sales stands out due to its customisation capabilities allowing businesses to order foam cut to size.

Throughout our interviews with these industry players, the resounding shared ethos was quality, consistency, and customer satisfaction.

Case Studies: Success Stories of Selecting the Right Foam Supplier

Over the years, FurnitureCo, an Australian furniture manufacturer, found tremendous success partnering with a reputable foam supplier. They saw a noticeable improvement in customer satisfaction due to better quality and more comfortable furniture. This partnership likely played a major role in FurnitureCo receiving the Best Furniture Company award in 2019, despite harsh competition.

Another case worthy of note is SleepRight, a mattress manufacturer, whose revenue significantly increased after partnering with high-quality foam suppliers for mattresses. An efficient supply chain and superior quality foam were critical factors in this growth.

Mistakes to Avoid While Choosing a Foam Supplier

Choosing a foam supplier requires a good deal of care and due diligence. Common mistakes companies often make include prioritising cost over quality, overlooking the significance of certificates and safety standards, and not adequately verifying a supplier’s reliability and delivery timeframes.

To avoid potential pitfalls, always do thorough research, ask the right questions, and insist on quality samples. Be vigilant for any potential red flags.

A Look into the Future: Technological Advances in Foam Production and Supply

Technology is playing a pivotal role in shaping the future of foam production. Modern machinery and cutting-edge production techniques are now being used to create more durable, higher quality foam at reduced costs. Moreover, technology is also facilitating better supply chain management, cutting down delivery times, and improving overall business efficiency.

In the coming years, we can expect further innovations and technological advancements which will continue to transform foam production and supply.

Conclusion

Selecting the right foam supplier can be critical to your business’s success. Keeping in mind the type of foam most suited to your requirements, the inherent qualities to look out for, the significance of certified standards, and the reliability of the supplier can help you make the right choice. Remember, consistency in quality and a good professional relationship with your supplier are often indicative of a successful partnership.