Equipment working at its full potential is the backbone of industrial operations. When the system requires motion control systems or variable speed, AC/DC drives become critically important. They govern the varying speeds of motors, enhance energy efficiency, and ensure that automated systems deliver smooth and consistent output. But like any equipment, drives also have to wear out over time. Regular servicing is required to ensure that they remain operational without fail.

Having a professional servicing keeps an issue from becoming a major breakdown. A lot of times, dust, heat, or vibrations get components to fail. The technician observes the early signs of such hazards and takes preventive action to avert damage. Proper inspection, therefore, ensures that your equipment is performing within safe limits, therefore cutting down risks and downtime.

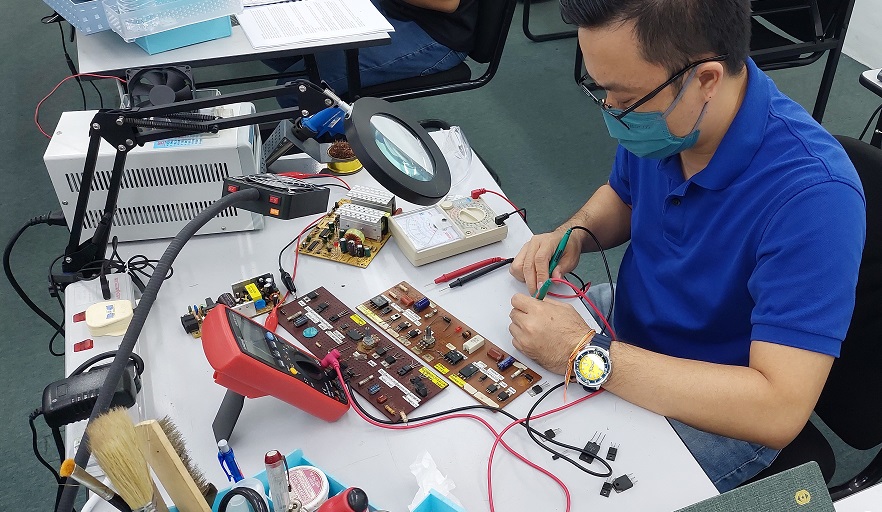

While AC drives and DC drives could be serviced differently, the main aspect differentiates them in the way the power is supplied. Fluctuation in input power could adversely affect AC drives, especially touching on their internal components, such as capacitors and IGBT modules. Very skilled professionals can take care of both, being able to replace parts that are worn out, clean the inner parts, and test the performance to assure output.

Prompted by the sunny benefits of timely maintenance, it goes without saying that it mitigates unplanned shutdowns, cuts down on repair costs, and prolongs machinery life. In that way, those savings translate to promoting a green environment.

Many industries, ranging from manufacturing to HVAC, require the drives to be continually working. Be it for conveyor belts or fans; they are essential components. Hence businesses trust professional service providers to service their drives. A technician functioning well will not just fix what is broken but improve reliability to avoid problems later.

Thermal scans, firmware updates, and testing under load consist, in most cases, of the service procedures. These guarantee that every part of the whole system works harmoniously. Small gains in efficiency begin to accumulate over time into big savings. With all that expertise and some assistance, less disruption means better results for businesses from their automation systems. So, the servicing of AC/DC drives, in actuality, is not only about maintenance but is approved as a wise productivity investment.